- Home

- Products

- About Us

- News

- Project

- Video

- Soliutions/Oem/Custom

- Contact Us

Industrial chillers are used in a variety of applications where chilled water or liquids are circulated through process equipment. Industrial chiller systems are typically used to cool products and machinery for many different applications including injection moulding, tooling and die cutting, food and beverage, chemicals, lasers, machine tools, semiconductors and many more.

Industrial chillers are used in a variety of applications where chilled water or liquids are circulated through process equipment. industrial chiller systems are typically used to cool products and machinery for many different applications including injection moulding, tooling and die cutting, food and beverage, chemicals, lasers, machine tools, semiconductors and many more.

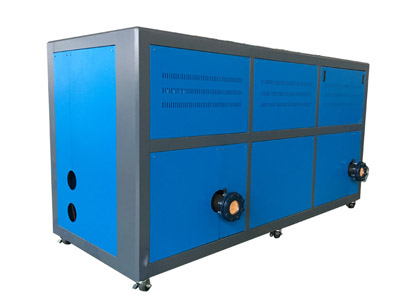

Air Cooled Scroll Chiller

The function of an industrial chiller is to transfer heat from one location (usually the process equipment or product) to another (usually the air outside the manufacturing facility). It is common to use water or a water/glycol solution to transfer heat in and out of the industrial chiller system, which may require the process chiller to have a reservoir and pump system. Whatever your industry and process, ensuring you have adequate cooling is essential for productivity and cost savings.

The series modular air cooled scroll chiller cooling capacity from 7KW to 120KW. Chilled units integrates the characteristics of many other products, using imported full-closed scroll compressors, supplemented by high-efficiency heat exchangers and adopts microcomputer controllers, which makes the unit compact, reasonable layout, convenient to use and maintain. The user just need simply connect the pipeline of the water system and the required power supply,then can put into operation.

This series of chillers is widely used: it can provide process chilled water for industrial and mining enterprises such as textile, chemical and petroleum. The manufacturing technology of this product is mature and stable and reliable. If you want to know more information about air cooled scroll chiller wholesale ,welcome to contact us today or request a quote.

Air Cooled Scroll Chiller

There are multiple benefits to using chillers to provide cooling. Chiller systems provide consistent temperatures and pressures for your industrial processes. Eliminating temperature and pressure variables simplifies process development and optimisation, ensuring the highest quality product. Refrigeration chillers recirculate cooling water rather than wasteful single-pass systems. Recirculation minimises water consumption costs, which can be expensive and environmentally unfriendly. View industrial chiller products.

In most process cooling applications, a pump system circulates chilled water or a water/glycol solution from the chiller to the process. This cold fluid removes heat from the process, while the hot fluid is returned to the chiller. Process water is the way in which heat is transferred from the process to the cooler.

The process cooler contains a compound called refrigerant. There are several types of refrigerant and applications depending on the temperature required, but they are all based on the basic principle of compression and phase change of the refrigerant from liquid to gas to liquid. This process of heating and cooling the refrigerant and changing it from a gas to a liquid and back again is the refrigeration cycle.

Water Cooled Scroll Chiller

The refrigeration cycle starts with a low pressure liquid/gas mixture entering the evaporator. In the evaporator, heat from the process water or water/glycol solution causes the refrigerant to boil, thus changing it from a low-pressure liquid to a low-pressure gas. The low pressure gas enters the compressor, where it is compressed into a high pressure gas. The high pressure gas enters the condenser, where ambient air or condenser water removes heat and cools it to a high pressure liquid. The high pressure liquid flows to the expansion valve, which controls the amount of liquid refrigerant entering the evaporator, thus restarting the refrigeration cycle.

There are two types of condenser used in water chillers; air cooled and water cooled. An air-cooled condenser uses ambient air to cool and condense the hot refrigerant gas into a liquid. It can be located either inside or outside the chiller, but eventually it discharges the heat from the chiller into the air. In a water-cooled condenser, water from a cooling tower cools and condenses the refrigerant.

Chiller systems come in a wide range of sizes and designs, and can be used as small, localised or portable chillers for smaller applications, or large central chillers designed to provide cooling for the entire process.

If you are interested in more detailed information on the best cooling solution for your application, please contact a Huazhao Refrigeration Equipment specialist.

Copyright © Water Cooled Chiller, Water Cooled Scroll Chiller Supplier China All Rights Reserved | Sitemap